Motion systems for vacuum applications

In addition to various types of chambers NTG also offers a series of different motion systems for vacuum applications. Our spectrum covers UHV linear feedthroughs and devices of different structural shape. Linear motion, rotation, tilting, pivoting – pneumatic or motor driven, we provide the full range:

- Pneumatic driven linear feedthroughs

- High precision linear feedthroughs

- Rotating chamber

- Adjustment devices

- And a lot more …

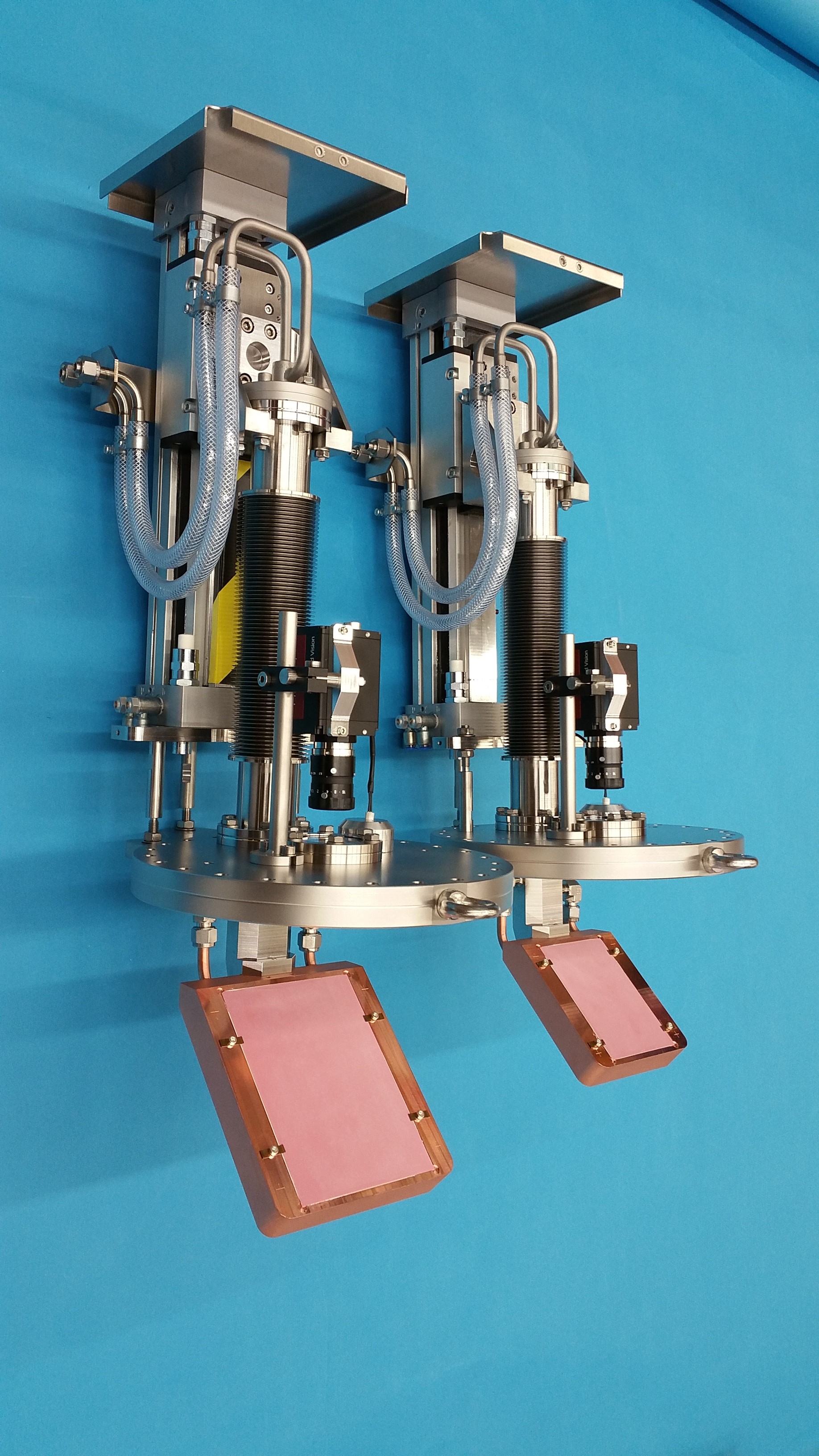

Pneumatic feedthroughs

The Feedthrough is provided for the “move in” and “move out” of elements in high vacuum systems.

Technical data:

Stroke: as required

Supporting flange: minimum diameter 100mm (CF or other)

Pressure: 4-6bar

Leak rate: < 10-10mbar*l/sec

Bakeout: bakeable to 300°C

Water cooling: cooling pipes inside the moving shaft

This Feedthrough is also available as a double version for independent movement of 2 different elements.

On request it is possible to deliver the feedthrough with an other flange system.

High precision linear feedthroughs

Our high precision linear feedthroughs are used if also discrete positions in the movement are important. Tuner, Wirescanners etc. for example are euqipped with these feedthroughs. Also here we provide full flexibility in design and configuration.

Technical data:

Stroke: as required (max. 250mm)

Supporting flange: minimum diameter 100mm (CF or other)

Pos. Accuracy: <10µm (depending on the type of stepper motor used)

Leak rate: <1e-10mbar*l/sec

Bakeout: bakeable to 300°C

Water cooling: cooling pipes inside the moving shaft available

Alternatively these feedthroughs are available as double units.

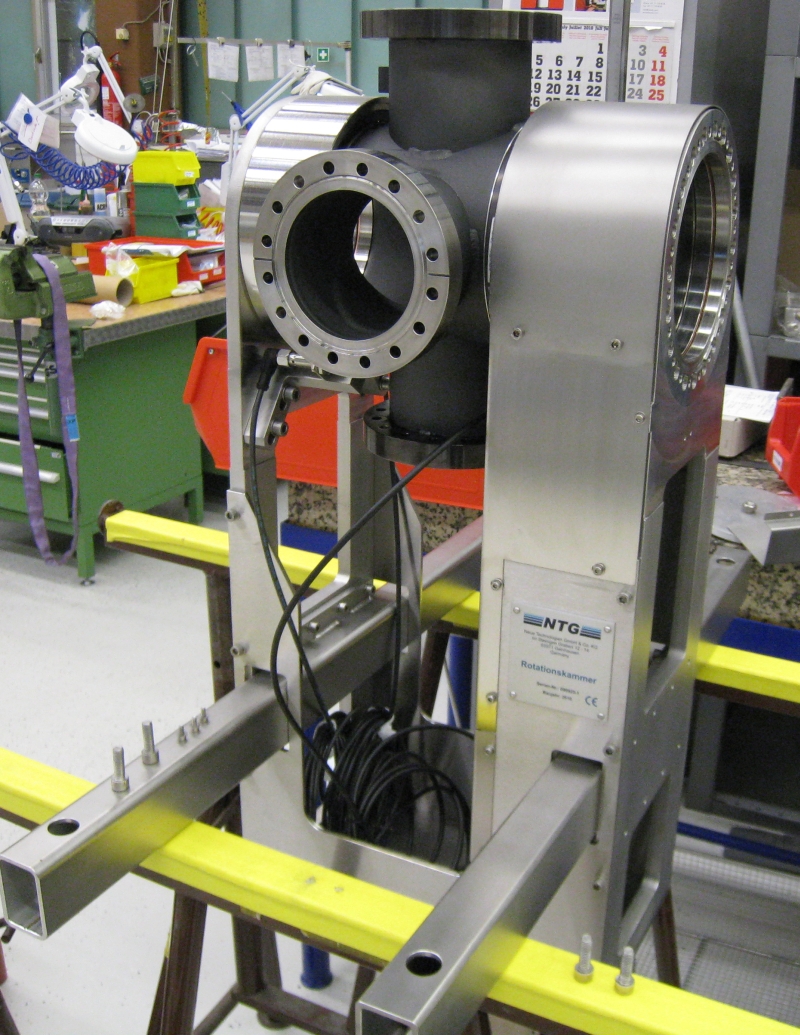

Rotating chambers

The Rotating mechanism enables to adjust two adjacent UHV chambers relatively to each other without breaking the vacuum. Another option is to use the rotating chamber for circular visual control (by camera or sensor).

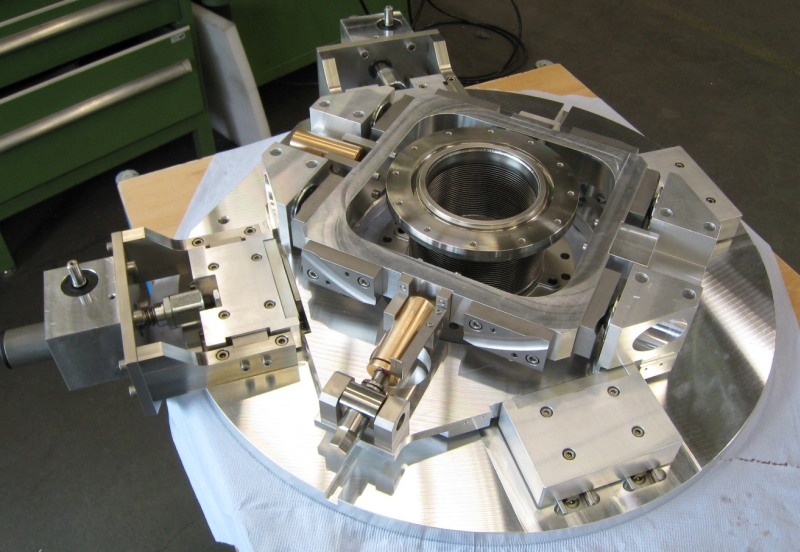

Adjustment devices

Adjustment and fine positioning of components (sensors, cameras,…) without breaking the vacuum is a major requirement in many vacuum applications. By using our special designed adjustment devices we can fullfill this need.

Adjustment can be done in two different planes, tilt angle is approx. +/- 3°. and the linear distance is up to +/- 4mm (motor driven).