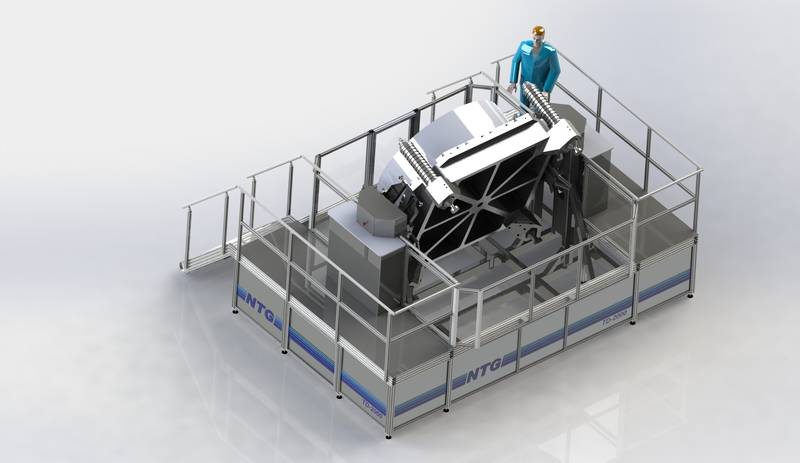

Turning device TD 2000

The Turning Device 2000 is a device for assembling, fine adjusting and turning optical components up to a diameter of 2000mm. The device is optimized for the use with an IBF 2000.

The original workpiece holder of the IBF 2000 can be adapted to the TD 2000 by using a lifting device (crane, etc.). The device is independent from the IBF plant, so it is possible to prepare a second substrate for IBF treatment while a first one is processed.

The TD 2000 is a semi-automatic, motor driven device. In case of any power loss the device stops at the current position. Safety precautions are implemented according to the actual state of the art and regulations.

The platform including two stairs enables easy, safe and convenient handling.

The operation is controlled via several push buttons located on the operating panel on the left platform side.

The footprint of the device is 4.7m(depth) by 5.3m(width), the maximum required height (workpiece in vertical orientation) is 3.8m.