Ion beam processing

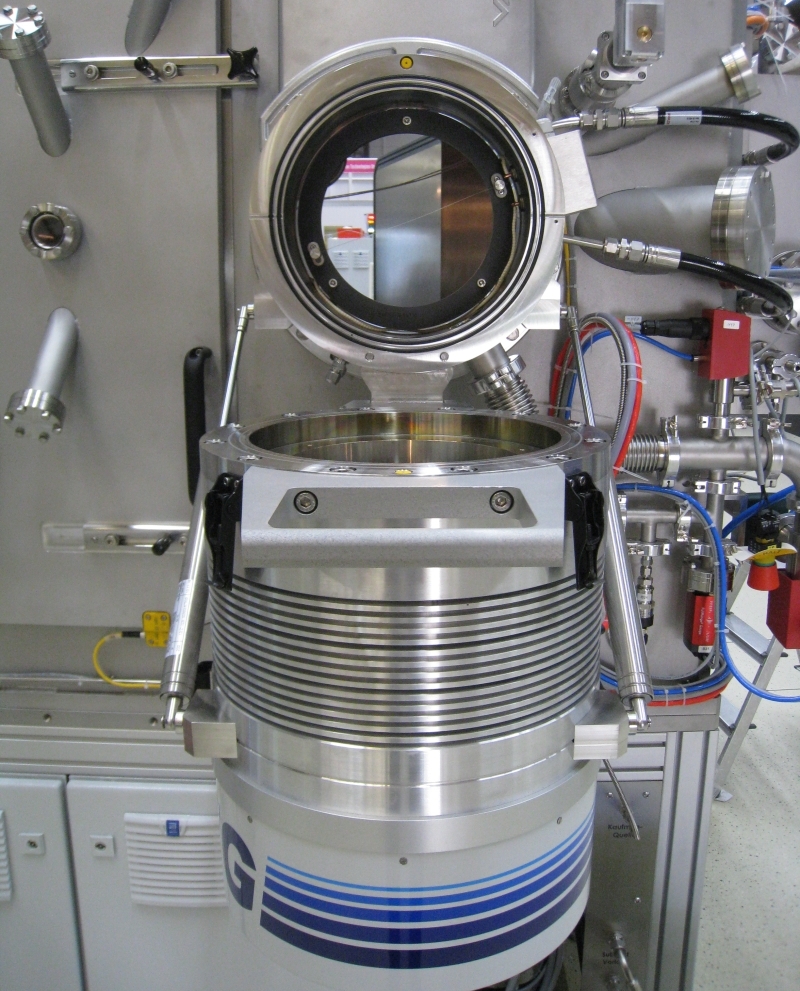

NTG started to develop Ion Beam Figuring plants in 1991 for the nanometer precise correction of surface errors, when only a few people in the world talked about Nanotechnology.

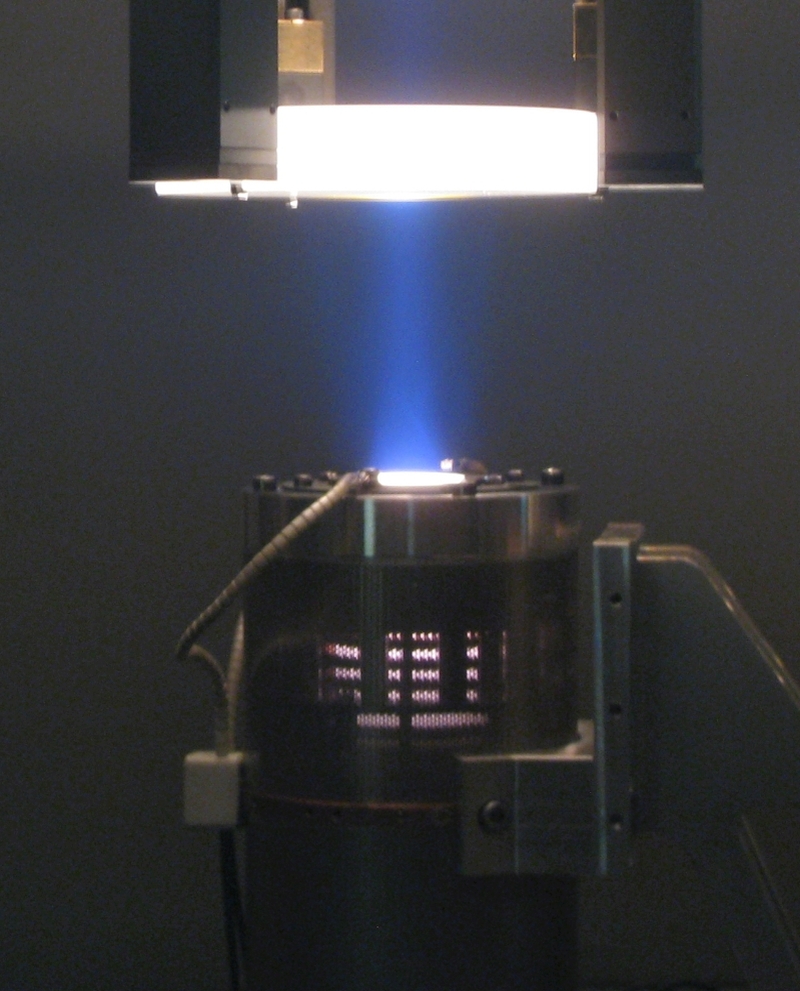

IBF

IBF(Ion Beam Figuring)-technology is needed when the required quality of the surface can not be achieved by using conventional polishing techniques. Our Customers are the world leader in fabrication of high performance optics.

Whereas in the past the use of technology was limited in producing stepper objectives for the semiconductor industry recently we recognize a growing demand of this technology even in the traditional optic industry.

R-IBE

Pattern transfers into hard materials (glass, …) are more and more of increasing importance. Also in this field NTG can provide a wide spectrum of solutions and Reactive Etching plants.

Additionally to the complete Ion Beam Etching and Figuring plants NTG also provides a wide range of accessories for IBF and R-IBE plants such as grid systems, work piece holders, loading and turning devices, sensors,….

Advantages of IBF-technology from NTG

- Contactless process – no signs on the surface

- no induced stress on the surface

- almost any geometry can be treated

- large spectrum of processable materials

- acquisition costs comparable with MRF plants

- low operating costs

– no abrasives are necessary

– nearly no wearing parts

– less cleaning exprenses (for parts and machine)

– low maintenance - surface quality PV < λ /10 to λ/20 achievable (depending on the

requirements of quality & process speed) - surface quality PV < λ/100, rms < 1nm achievable without

additional investments - Know-How resulting of more than 25 years IBF-treatment