Our latest generation of the IBF200 is specially designed for industrial series production of workpieces with a diameter of 200mm and a weight of 15kg. Likewise, components up to 300mm, depending on the process up to 350mm, can be machined by direct loading and associated longer pumping times.

Here you´ll find the PDF

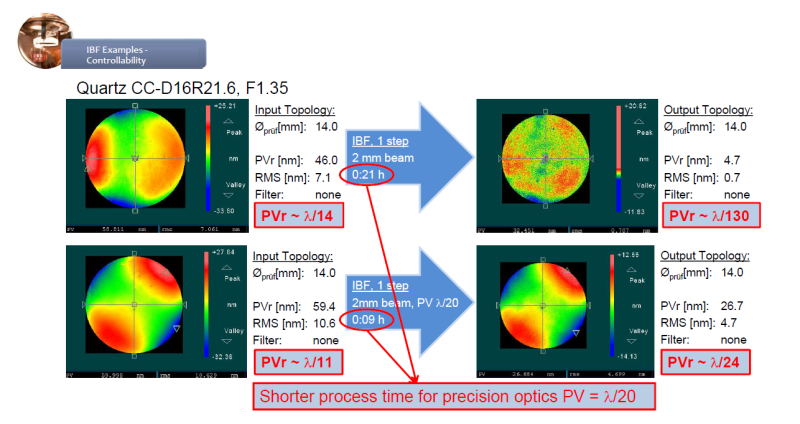

A 24/7 operation with cycle times of 2-3 min allows high quantities even with small optics and shorter machining times. The tool change is semi-automatic, so that the process chamber no longer needs to be ventilated. Downtimes are thus reduced to a minimum. Average maintenance intervals of several 100 hours allow for targeted time planning. Furthermore, the processes can be defined to precisely defined target values (PV, RMS). An example is shown below, here the processing time can be halved.

The system is optionally available in a 3-axis or 5-axis configuration. This means that IBE or IBS processes can also be realised.

You can find further information on our homepage: IBF 200