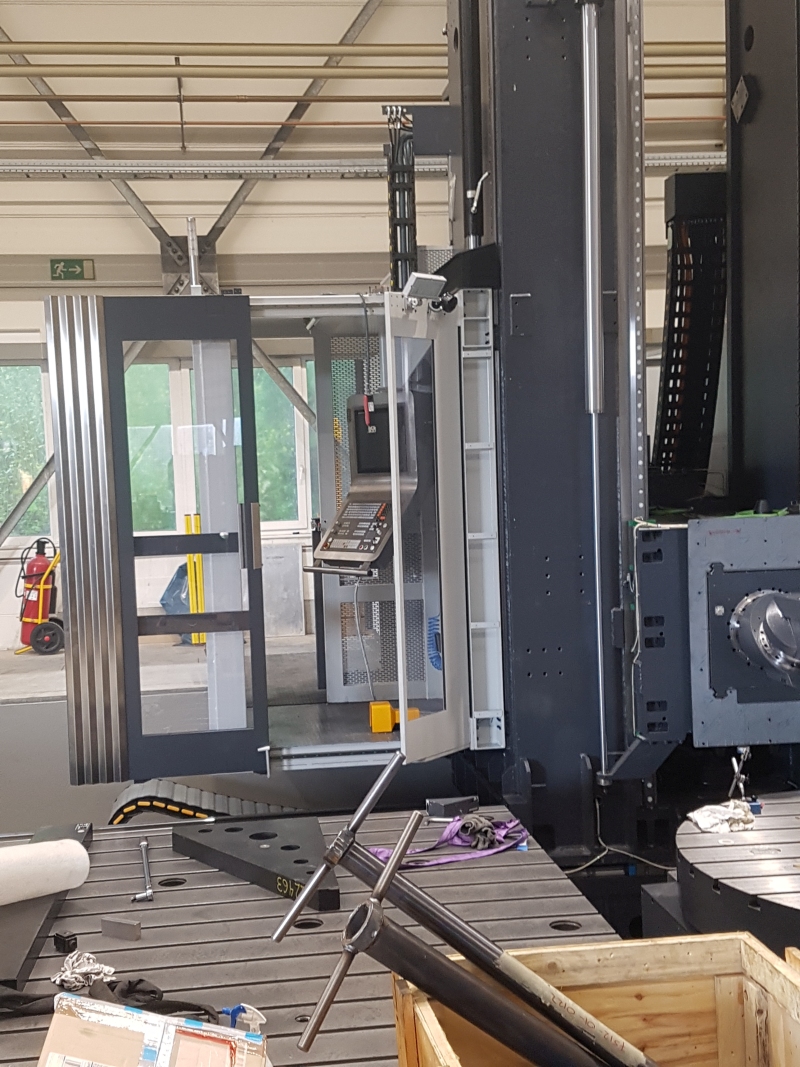

The latest and largest investment in terms of dimensions has recently been integrated into our machine park. With the successful commissioning of the Correa Magna-75 travelling column milling machine, even the largest components can now be manufactured at NTG. Mechanical components up to a length of 7.5m and a height of up to 4m with a total weight of up to 20t can be milled with highest precision in one clamping.

The insertion process turned out to be much more complex than expected. The ground-level arrangement of the machine’s plate fields required a 4m-deep foundation. This was additionally secured with 47 concrete piles sunk into the ground to a depth of up to 7m. The construction for the foundation itself took more than 7 months. The actual installation of the machine also required measured work, as the tower of the machine extends up to a few centimeters below the hall crane.

The flexibility of NTG’s own production is considerably increased by this investment and meets the most demanding requirements. We are also happy to provide the machine for the production of your components. We are looking forward to your inquiries

Here you can see the Correa Magna 75 travelling column milling machine in action

Technical data:

Travels: (x,y,z): 7.500 x 1.500 x 4.000 mm – 5 axes

spindle motor: 52 kW – 1.375 Nm – 6.000 rpm

1st plate field: 4.500 x 3.000 x 300 mm

2nd plate field: 1.500 x 3.000 x 300 mm

rotary table: ø 2.000 mm – 20 t

Linear axis: W=1,500 mm – 20t