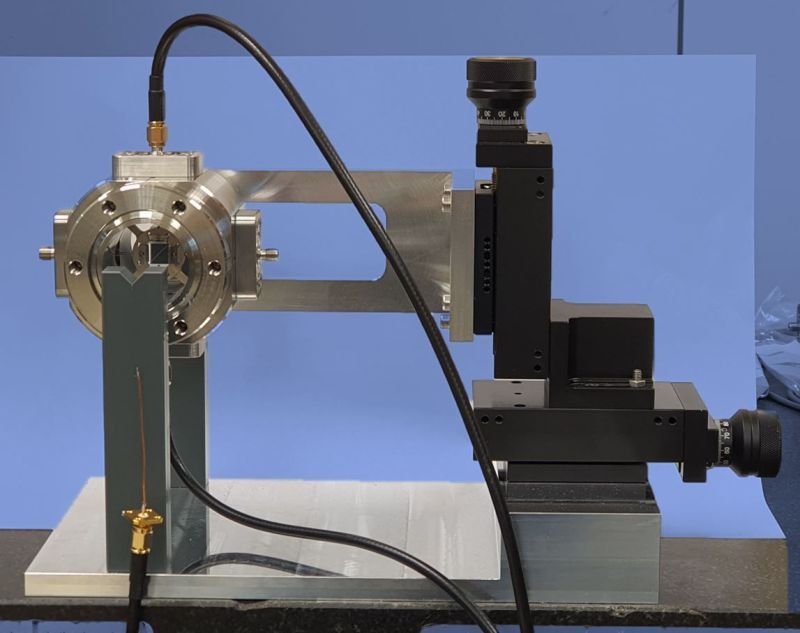

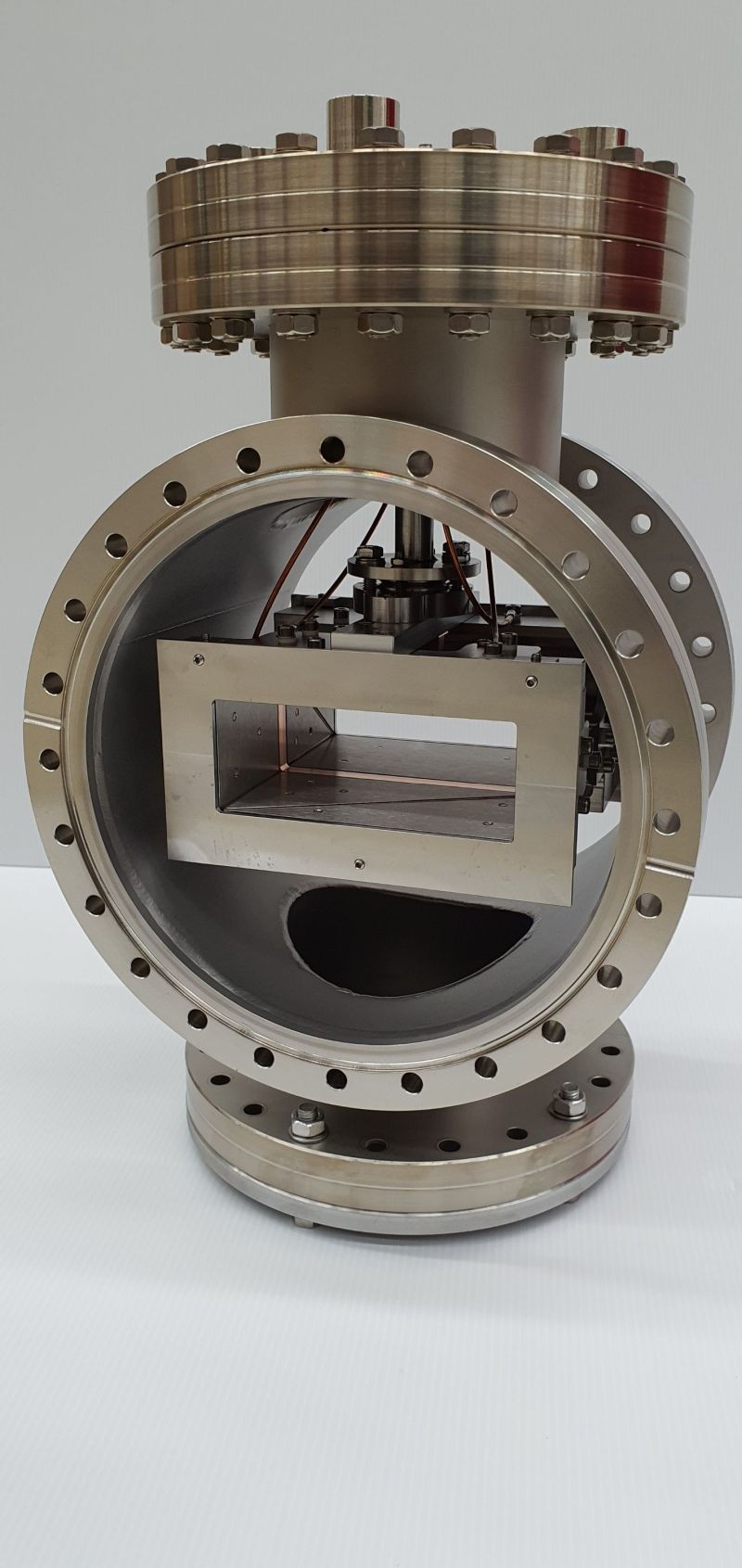

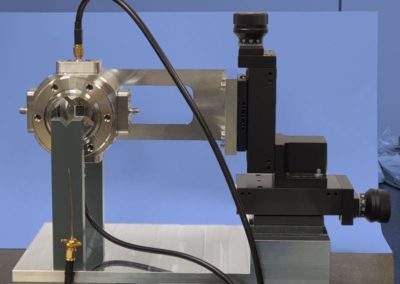

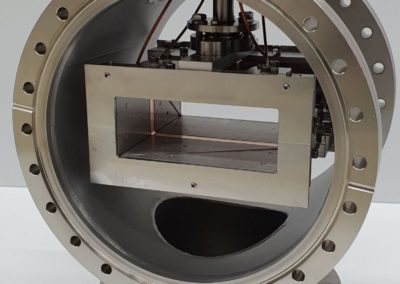

In the field of beam diagnostics, a new test method has been established at NTG. For the second time, we are supplying capacitive position probes, in one case Beam Position Monitors and in the other linear-cut Shoeboxes, which have been calibrated by means of a wire with a high-frequency alternating voltage. The operating principle of these probes is based on the influence of a charge displacement on the electrodes which are symmetrically arranged around the beam. This charge displacement can be measured as an electric current. If it is the same on the corresponding electrodes, the beam is on the axis of symmetry. Due to the design and for manufacturing reasons, the geometric axis of symmetry is not always exactly on the electrical symmetry axis. Our new test method measures exactly this deviation. The electromagnetic field of the wire simulates the field of a beam of charged particles (ions, electrons). Via the exact position of the wire, we obtain the desired information about the symmetry ratios. But be careful, with such high precision requirements, possibly the changed boundary conditions in the final installation situation must not be neglected. Often there is an acute lack of space and the diagnostic elements have to be adapted accordingly. This means that the sensitive probe elements tend to move to the periphery of the unit and thus become sensitive to the environment. Here, constructive measures may have to be taken in advance or, if possible, calibration in the final installation situation is recommended. We will be happy to advise you on the specific application.

If we have aroused your interest with this article, you are welcome to contact us.

Here you can find more information about beam diagnostics.