Bi-metal CF flange connections

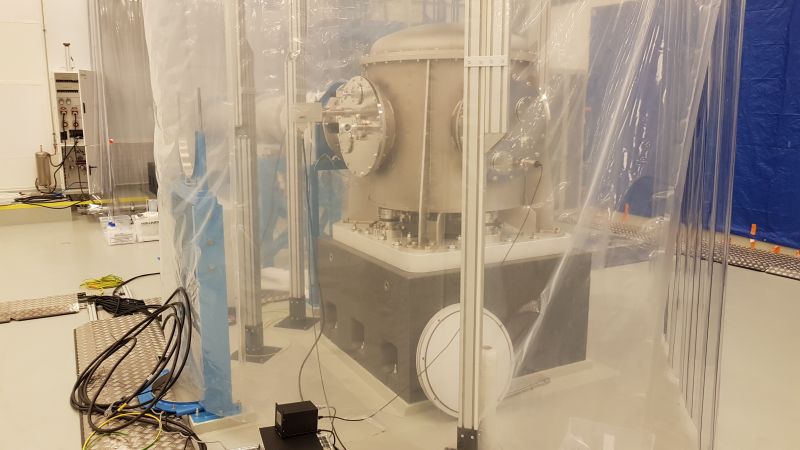

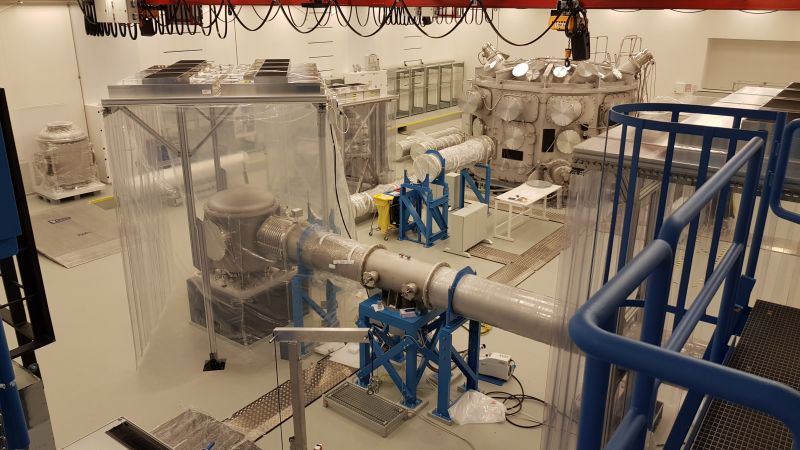

CF flanges are a standard for UHV applications. They can be heated out and are suitable for pressures less than 1×10-12 mbar. In many cases 1.4301/1.4307 is sufficient, but if higher requirements are needed, e.g. regarding material strength or lowest possible magnetizability, 1.4429 ESU is most commonly used.

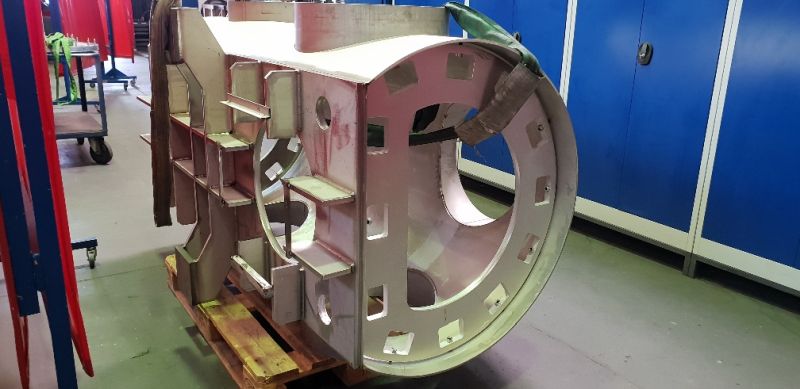

Since aluminum is becoming increasingly popular in the vacuum industry due to its very low outgassing rate, low magnetizability and excellent machinability, the benefits of our bimetallic CF flanges come into play here. These flanges are fully compatible with the industry standard CF flange. The combination of both materials (aluminum/stainless steel) allows welding to aluminum vacuum chambers with the simultaneous availability of a stainless steel cutting edge.

Our fusion process allows not only standard CF flanges, but also customized solutions, such as special contours or internally cooled flanges.

The following material combinations are feasible:

– Aluminum: EN AW 5754

– Stainless steel: 1.4301, 1.4404, 1.4429 ESU

Helium leakage test:

Q < 1 x 10-9 mbar l/s

Applicable temperature range:

-196 °C to +250 °C

Permeability:

< 1,005

We hope this article has aroused your interest and are looking forward to your feedback.

If you have any questions about CF flanges or a special application, please feel free to contact us.