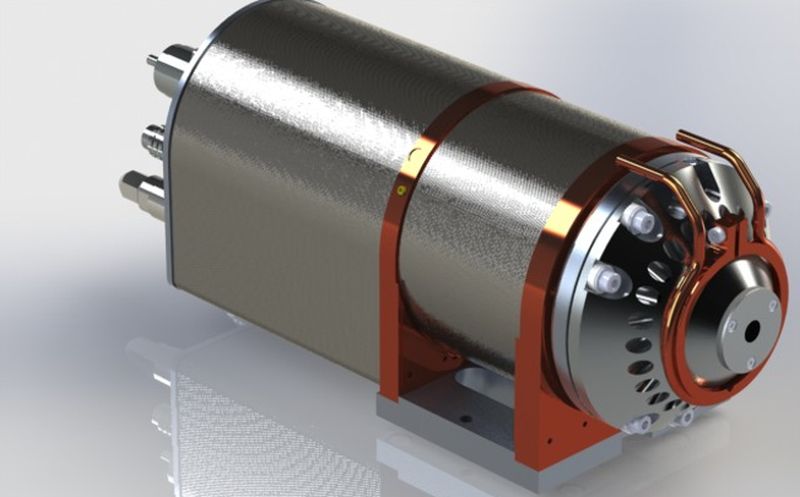

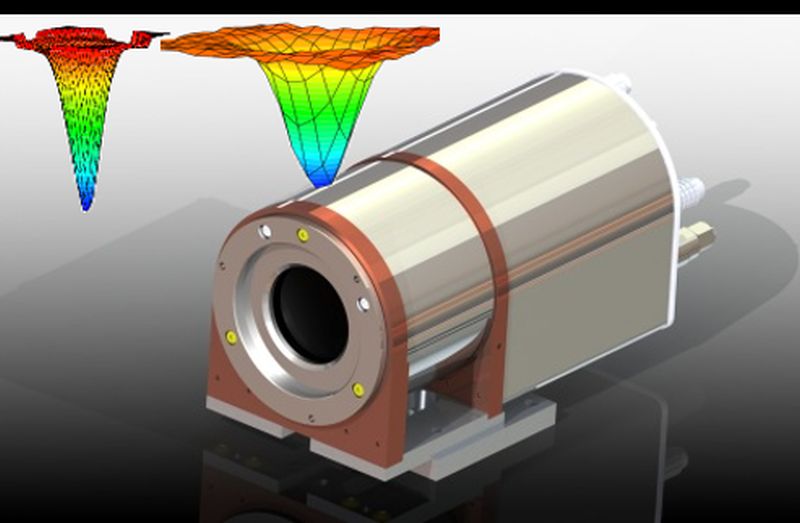

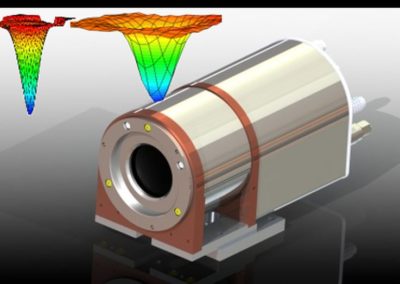

Review of the 2nd NTG IBF conference in 2018

In the anniversary year >> 50 years of NTG << the NTG organized its 2nd International IBF Conference with 70 participants from 10 countries.

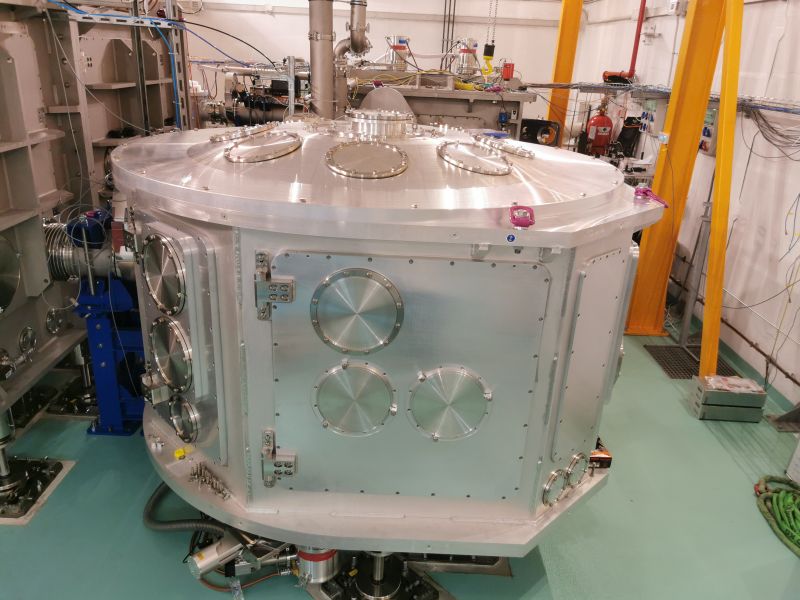

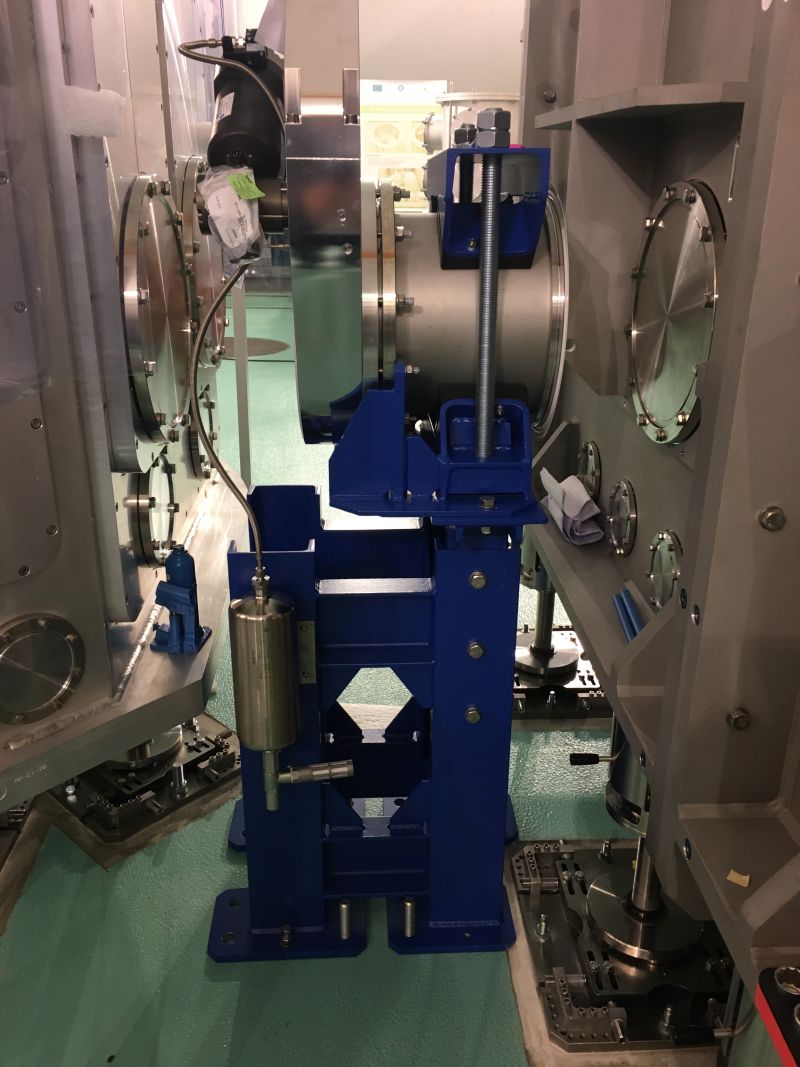

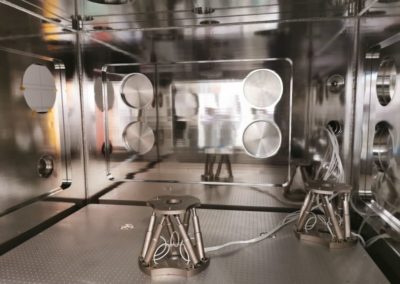

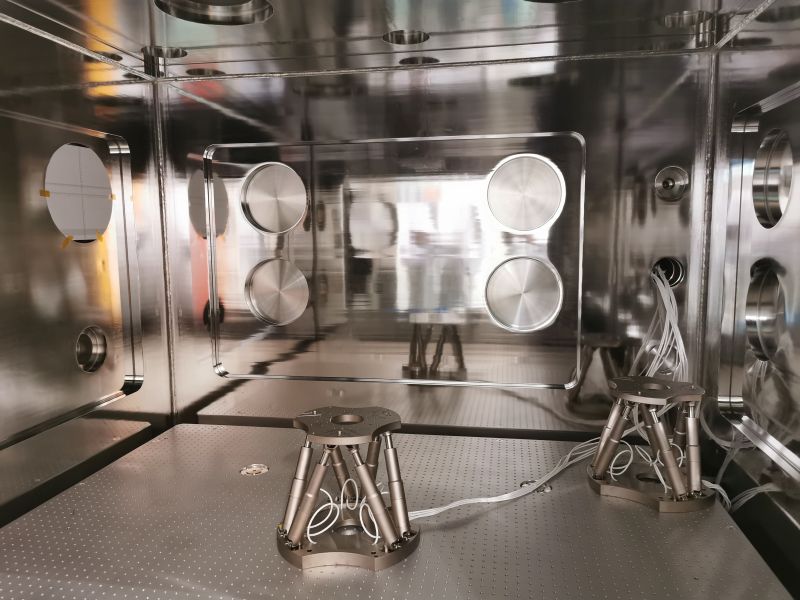

Many high-ranking speakers presented innovative ideas and novel areas of application for our IBF and IBE systems.

We are already preparing to host the 3rd international NTG IBF conference in 2022. For more information, follow one of our next posts. We hope that we will then again be able to welcome experts from many countries to revive the international exchange from person to person.

We look forward to you!